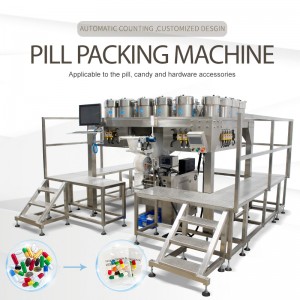

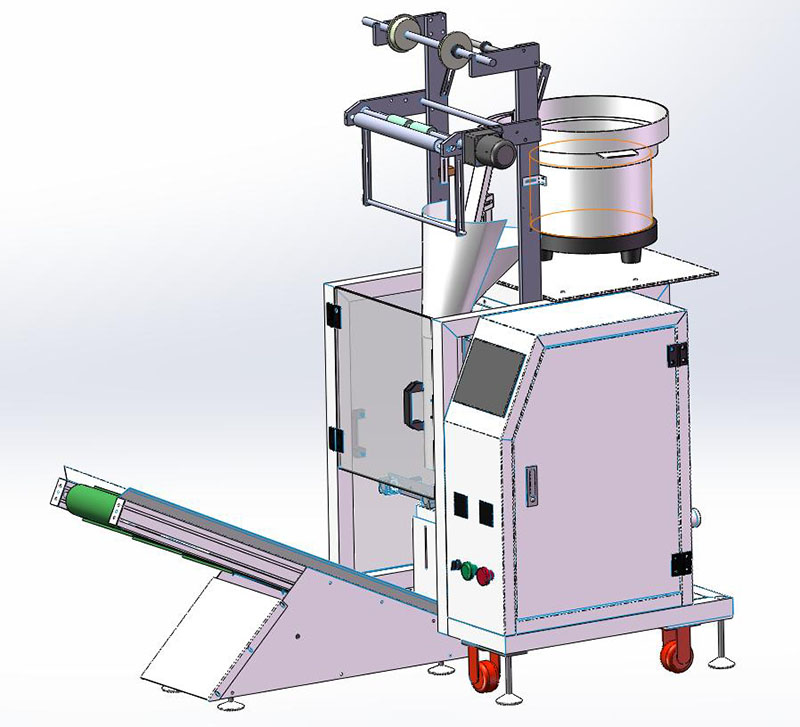

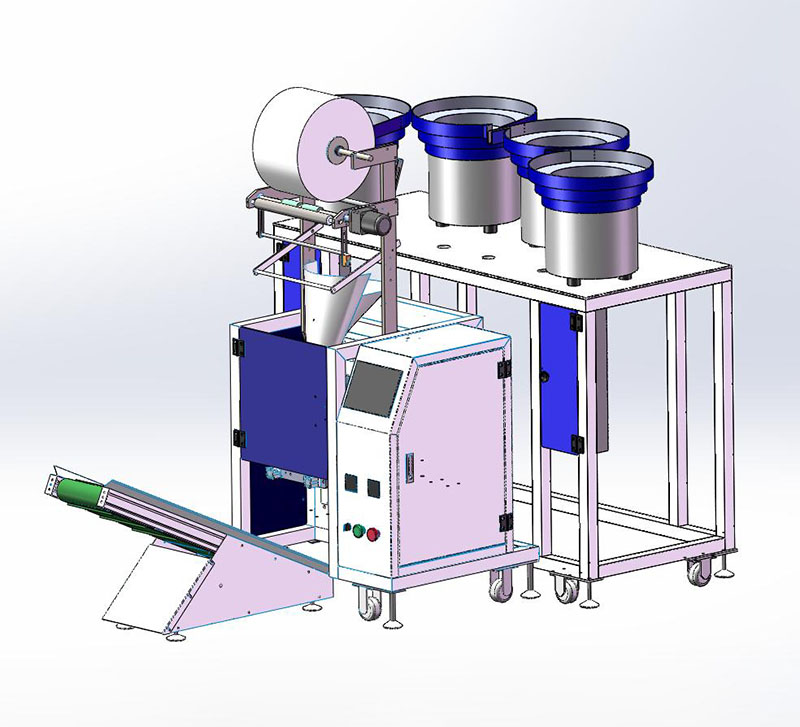

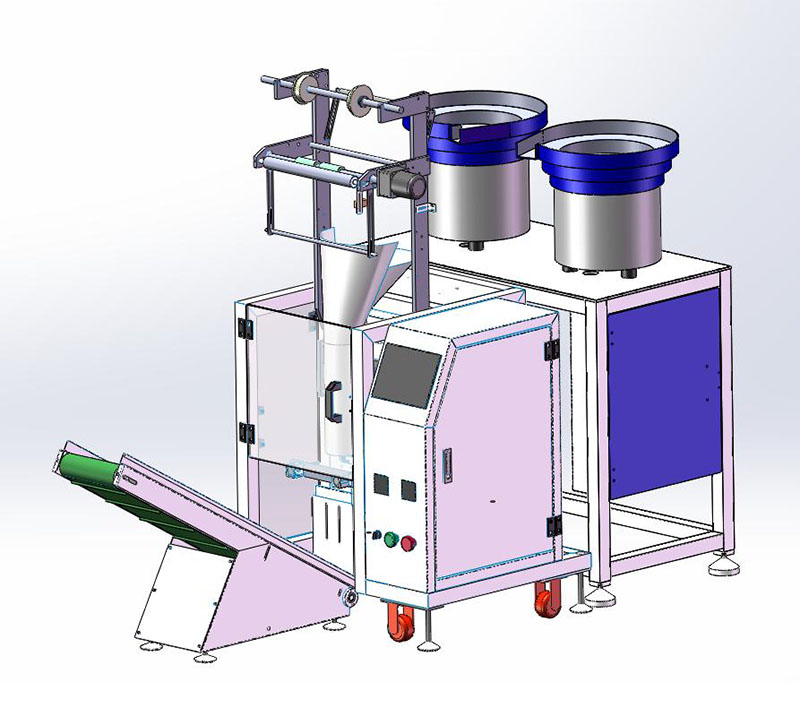

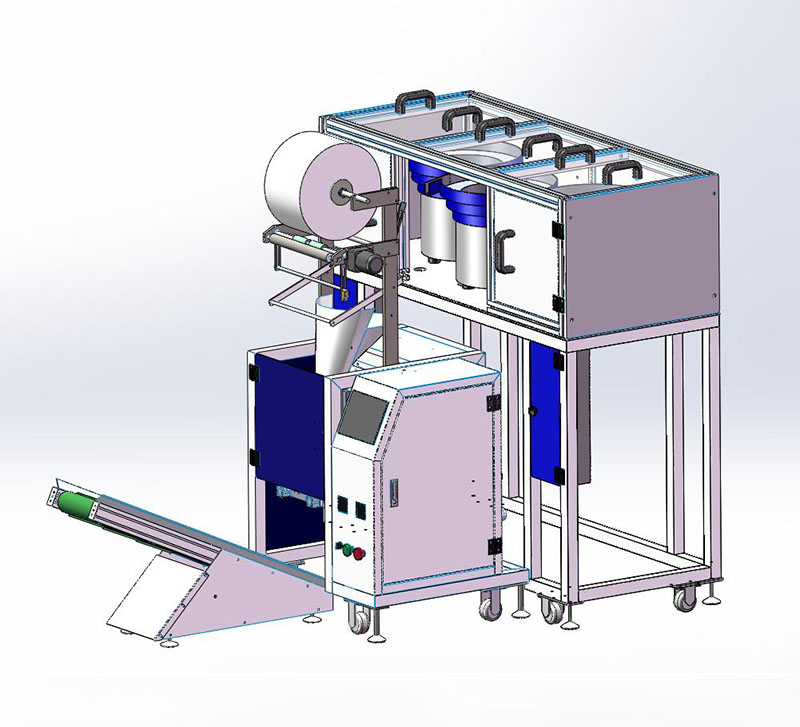

Automatic Screw Packaging Machine

Automatic Screw Packaging Machine

A Intelligent Packaging Equipment Customization

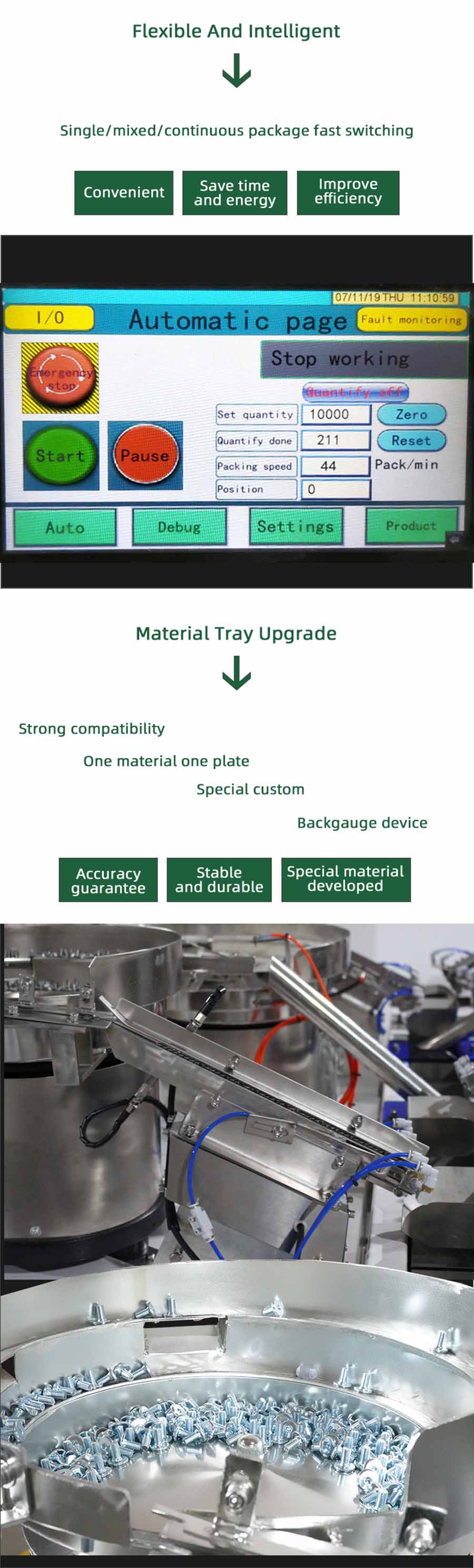

Applicable to single items packing and mixed 2-4 kinds of items packing.

Hardware Counting Packing Machine Applicable Industry:

Furniture, Fasteners, Toy, Electrical, Stationery, Pipe, Vehicle etc.

PLC control system, 7 inch touch screen, easy operation and multiple language for choice.

Fiber counting system, vibrating bowl with high accuracy fiber counting device.

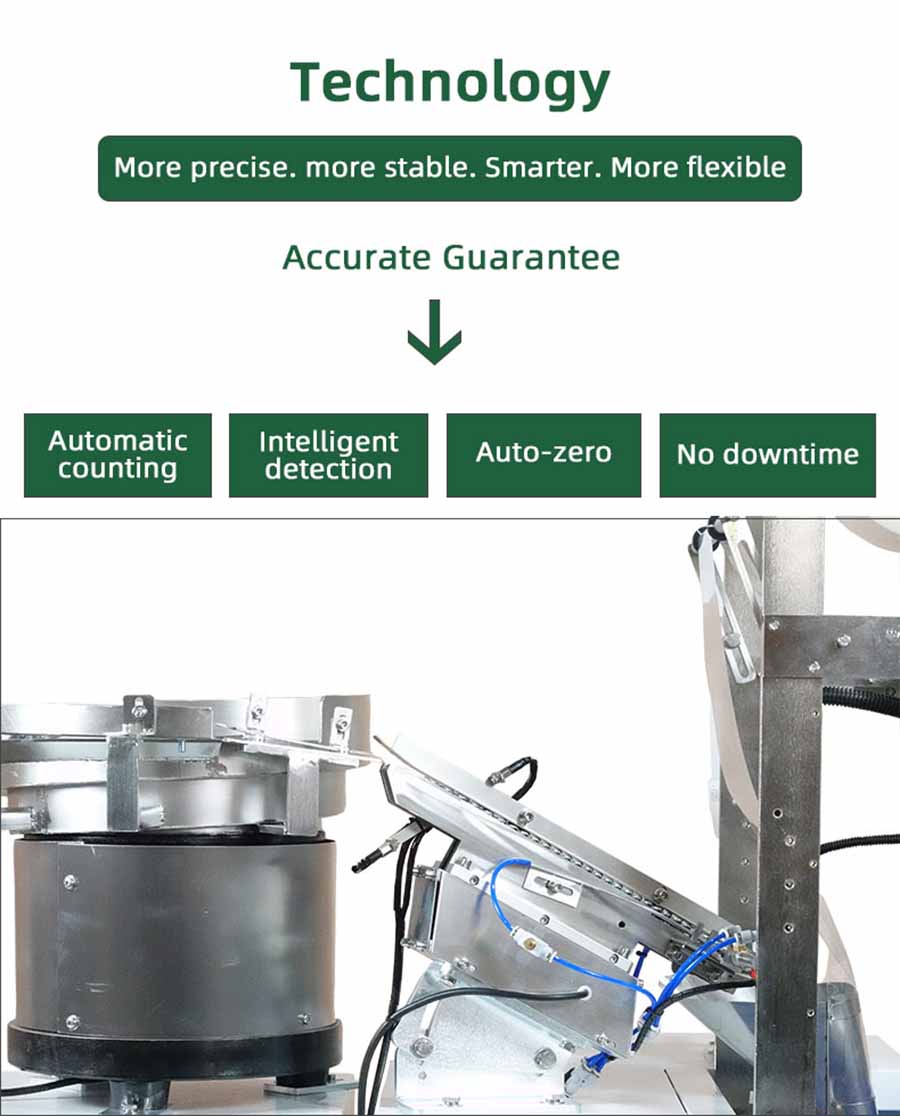

Technology: More precise more stable, smarter, more flexible

Accurate Guarantee

• Automatic counting

• Intelligent detection

• Auto-zero

• No downtime

FAQ

Q: How does the vibrator bowl work?

A: Vibrator bowl is mainly composed of hopper, chassis, controller, linear feeder and other supporting components. It can also be used for sorting, testing, counting and packaging. It is a modern high-tech product.

Q: What are the possible reasons why the vibrator bowl does not work?

A: Possible causes of vibration plate not working:

1. Insufficient power supply voltage;

2. the connection between the vibration plate and the controller is broken;

3. The controller fuse is blown;

4. coil burned off;

5. the gap between the coil and the skeleton is too small or too large;

6. There are parts stuck between the coil and the skeleton.

Q: Automatic equipment common fault diagnosis

A: Check all power sources, air sources, hydraulic sources:

Power supply, including the power supply of each equipment and the power of the workshop, that is, all the power supply that the equipment can involve.

Air source, including air pressure source for pneumatic device.

Hydraulic source, including hydraulic device required hydraulic pump operation.

In 50% of fault diagnosis problems, errors are basically caused by power, air and hydraulic sources. For example, power supply problems, including the failure of the entire workshop power supply, such as low power, insurance burned, power plug contact poor; The air pump or hydraulic pump is not opened, the pneumatic triplet or two couplet is not opened, the relief valve or some pressure valve in the hydraulic system is not opened, etc. The most basic questions are often the most common.

Check whether the sensor position is offset:

Due to the negligence of equipment maintenance personnel, some sensors may be wrong, such as not in place, sensor failure, sensitivity failure, etc. To often check the sensor sensor position and sensitivity, deviation in time adjustment, if the sensor is broken, immediately replace. A lot of times, if the power, gas and hydraulic supply is correct, more of the problem is sensor failure. Especially the magnetic induction sensor, due to long-term use, it is likely that the internal iron is stuck to each other, can not be separated, there are normally closed signals, which is also the common fault of this type of sensor, can only be replaced. In addition, due to the vibration of the equipment, most of the sensors will be loose after long-term use, so in daily maintenance, we should often check whether the position of the sensor is correct and whether it is fixed firmly.

Check relay, flow control valve, pressure control valve:

Relay and magnetic induction sensor, long-term use will also appear the situation of bonding, so as to ensure the normal electrical circuit, need to be replaced. In the pneumatic or hydraulic system, the throttle valve opening and the pressure regulating spring of the pressure valve will also appear loose or sliding with the vibration of the equipment. These devices, like sensors, are part of the equipment that requires routine maintenance. So in daily work, be sure to carry out careful inspection of these devices.

Factory

Honor and qualification

images

Team

exhibition

group photo

travel

performance