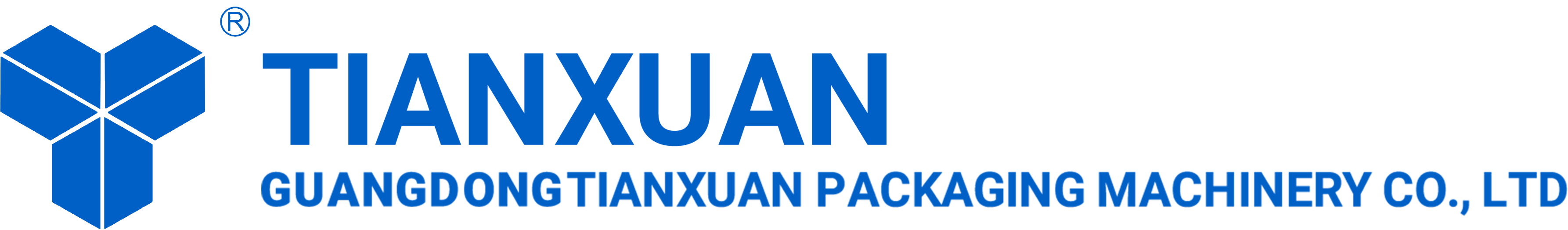

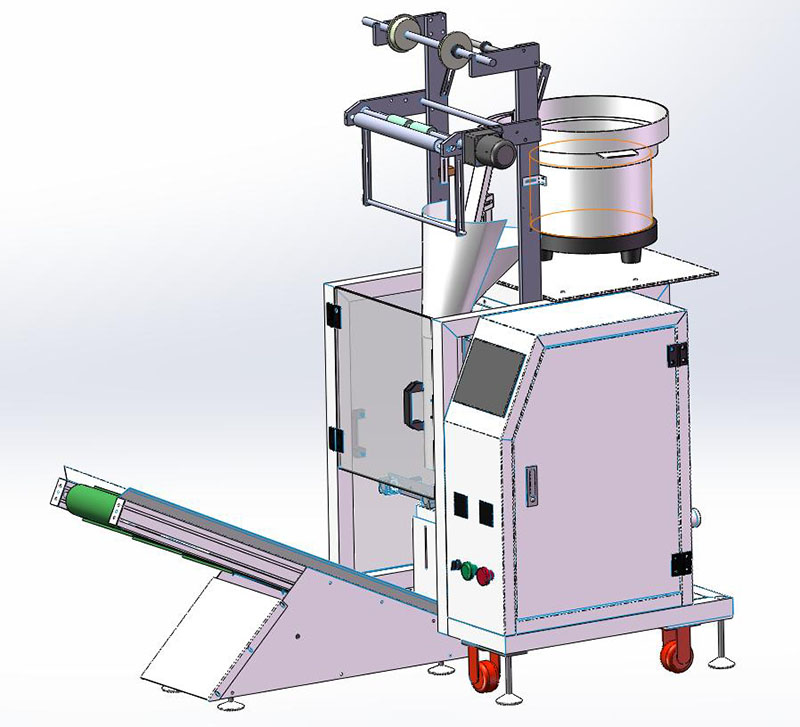

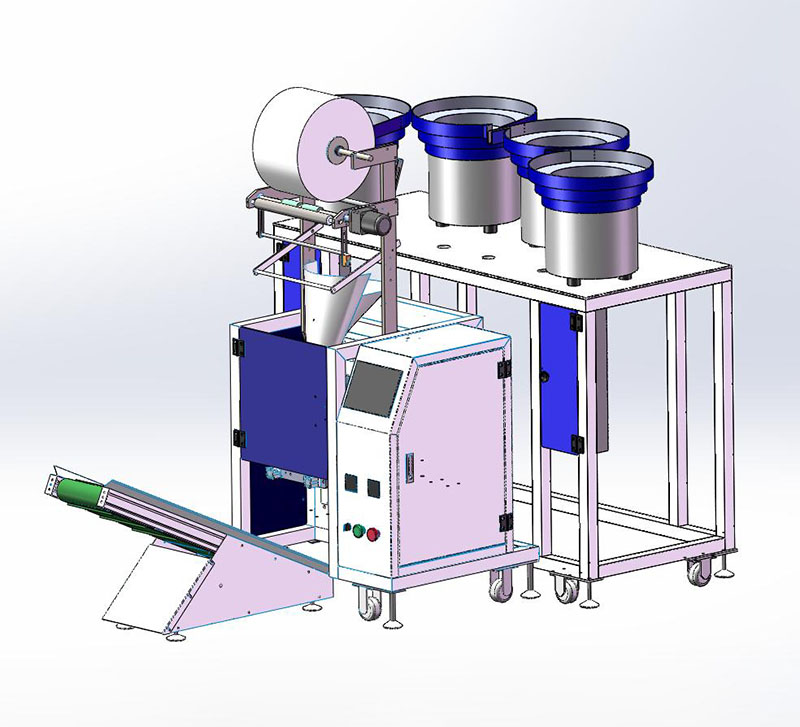

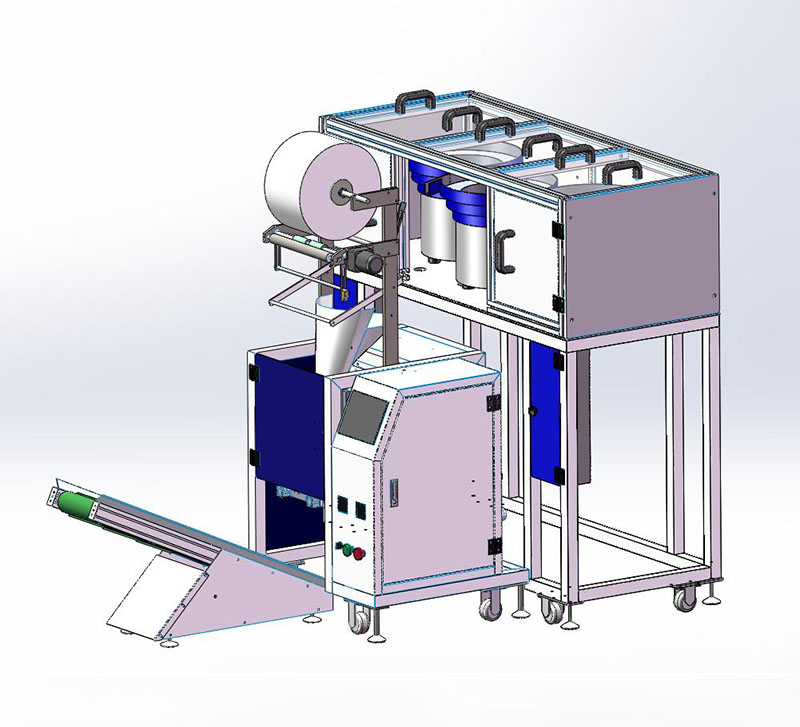

Mashiinka Baakadaha Tooska ah

Mashiinka Baakadaha Tooska ah

Habaynta Qalabka Baakadaha Caqliga leh

Lagu dabaqi karo baakad hal shay iyo 2-4 nooc oo shay ah oo la isku daray.

Mashiinka Xirmooyinka Tirinta Hardware Warshada lagu dabaqi karo:

Alaabooyinka, Xajiyeyaasha, Toy-ga, Korontada, Qalabaynta, Dhuumaha, Gaadhiga iwm.

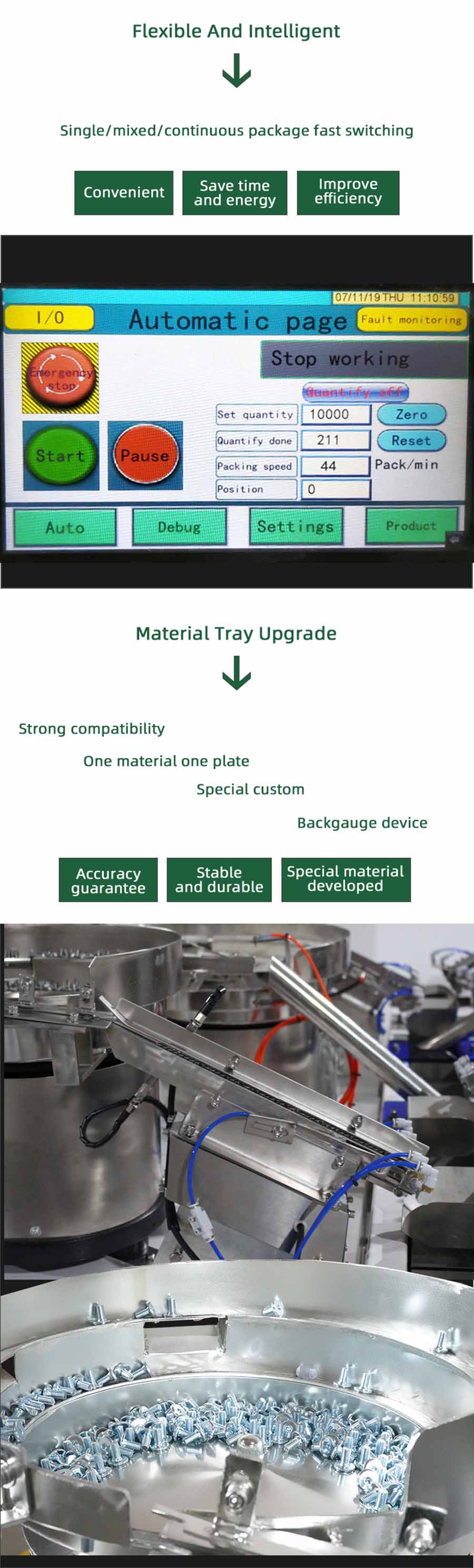

Nidaamka xakamaynta PLC, 7 inch touch screen, hawl fudud iyo luqado badan oo doorasho ah.

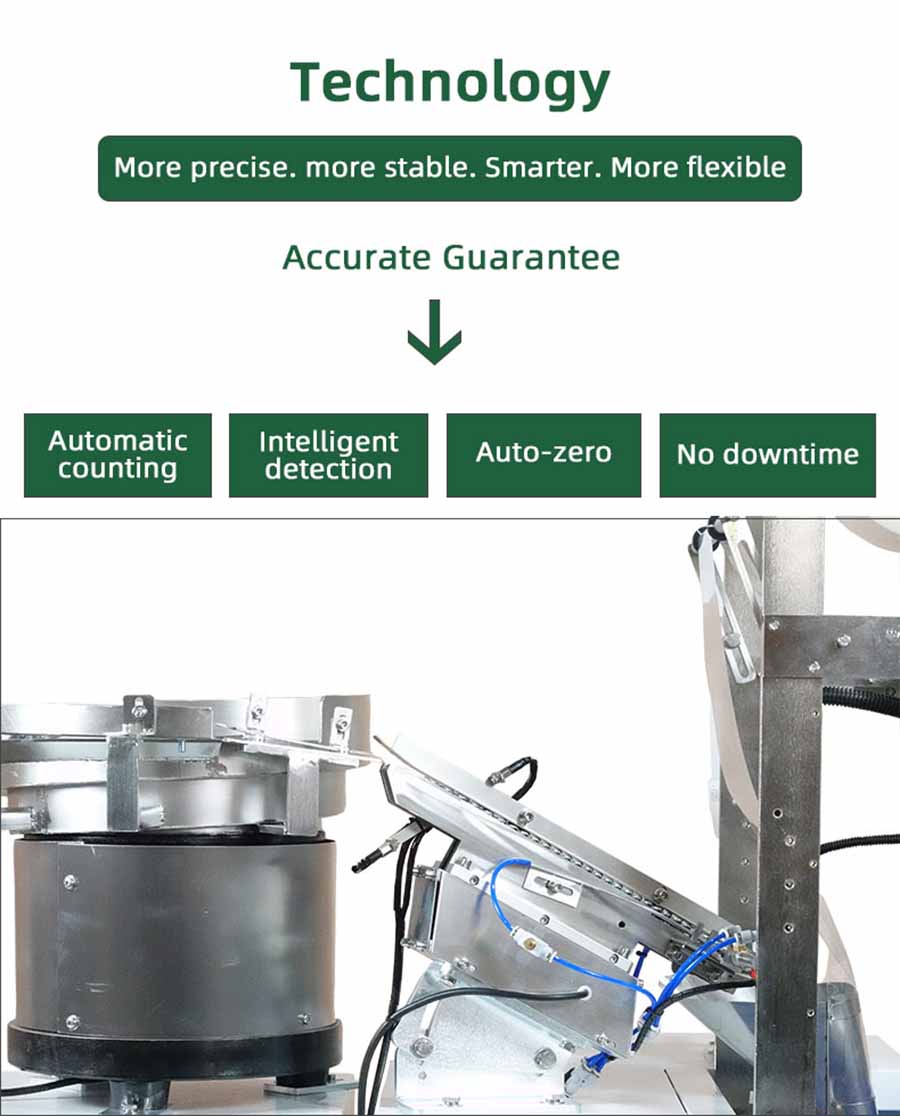

Nidaamka tirinta fiber-ka, baaquli gariir leh oo leh aaladda tirinta fayraska saxnaanta sare.

Farsamada:Si sax ah u deggan, ka caqli badan, dabacsanaan badan

Dammaanad sax ah

• Tirinta tooska ah

Ogaanshaha garaadka

Si otomaatig ah

• Ma jiro waqti dhimis

FAQ

S: Sidee buu u shaqeeyaa baaquli gariirka?

J: Makiinada gariirka waxay inta badan ka kooban tahay hopper, chassis, controller, feeder toos ah iyo qaybo kale oo taageeraya.Waxa kale oo loo isticmaali karaa kala-soocidda, tijaabinta, tirinta iyo baakaynta.Waa badeeco casri ah oo tignoolajiyada sare leh.

S: Maxay yihiin sababaha suurtogalka ah ee baaquli gariirku u shaqayn waayo?

J: Sababaha suurtogalka ah ee saxanka gariirka oo aan shaqaynayn:

1. Koronto aan ku filnayn;

2. xidhiidhka ka dhexeeya saxanka gariirka iyo kontoroolka ayaa jabay;

3. Fiyuuska kantaroolaha waa la afuufay;

4. gariiradda gubatay;

5. Farqiga u dhexeeya gariiradda iyo qalfoofka oo aad u yar ama aad u weyn;

6. Waxa jira qaybo ku dheggan gariiradda iyo qalfoofka dhexdooda.

S: Qalab otomaatig ah ogaanshaha cilladda guud

J: Hubi dhammaan ilaha tamarta, ilaha hawada, ilaha hawo-biyoodka:

Korontada, oo ay ku jiraan quwadda qalab kasta iyo awoodda aqoon-is-weydaarsiga, taas oo ah, dhammaan tamarta korontada ee qalabku ku lug yeelan karo.

Ilaha hawada, oo ay ku jiraan isha cadaadiska hawada ee aaladaha pneumatic.

Isha Haydarooliga, oo ay ku jirto aaladda hawo-biyoodka ee loo baahan yahay hawlgalka bamka haydarooliga.

50% dhibaatooyinka ogaanshaha cilladda, khaladaadka asal ahaan waxaa sababa koronto, hawo iyo ilo biyo-biyood ah.Tusaale ahaan, dhibaatooyinka sahayda korantada, oo ay ku jiraan fashilka dhammaan sahaydii aqoon-is-weydaarsiga, sida tamarta yar, caymiska gubtay, xidhidh koronto oo liita;Bamka hawada ama bamka hawo-qaadista lama furin, sadxeeyaha pneumatic ama laba lammaane lama furin, valve gargaarka ama valve cadaadiska ee nidaamka hawo-qaadista lama furin, iwm. Su'aalaha aasaasiga ah ayaa badanaa ah kuwa ugu badan.

Hubi in booska dareemaha uu ka baxay:

Sababtoo ah dayacaadda shaqaalaha dayactirka qalabka, dareemayaasha qaar ayaa laga yaabaa inay khaldan yihiin, sida aan meesha ku jirin, cilladda dareenka, cilladda dareenka, iwm. Si aad inta badan u hubiso booska dareenka dareenka iyo dareenka, leexashada wakhtiga hagaajinta, haddii dareemuhu jabo. isla markiiba beddel.Marar badan, haddii tamarta, gaaska iyo sahayda hydraulic ay sax tahay, in badan oo dhibaatadu waa cillad dareemeed.Gaar ahaan dareemaha induction magnetic, sababtoo ah isticmaalka muddada dheer, waxay u badan tahay in birta gudaha ay ku dheggan tahay midba midka kale, lama kala saari karo, waxaa jira calaamado caadi ah oo xiran, taas oo sidoo kale ah qaladka caadiga ah ee nooca dareenka, kaliya lagu badalo.Intaa waxaa dheer, sababtoo ah gariirka qalabka, inta badan dareemayaasha ayaa dabacsanaan doona ka dib isticmaalka muddada dheer, sidaas darteed dayactirka maalinlaha ah, waa in aan inta badan hubinaa in booska dareemaha uu sax yahay iyo haddii uu si adag u go'an yahay.

Hubi gudbinta, waalka kantaroolka socodka, waalka xakamaynta cadaadiska:

Relay iyo magnetic induction sensor, isticmaalka muddada dheer ayaa sidoo kale u muuqan doona xaaladda isku xirnaanta, si loo hubiyo wareegga korantada ee caadiga ah, waxay u baahan yihiin in la beddelo.Nidaamka pneumatic-ka ama hadhka, furitaanka waalka ceejinta iyo cadaadiska nidaaminaya guga waalka cadaadiska ayaa sidoo kale u muuqan doona dabacsan ama simbiriirixan iyada oo la gariirayo qalabka.Qalabkan, sida dareemayaasha, waa qayb ka mid ah qalabka u baahan dayactir joogto ah.Markaa shaqada maalinlaha ah, hubi inaad si taxadar leh u kormeerto qalabkan.