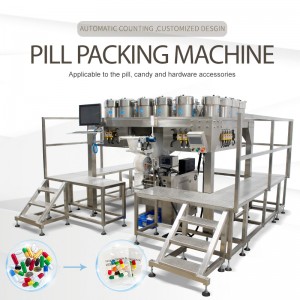

Vibratory Bowl Feed And Weigh System

Automatic Weigher

Application

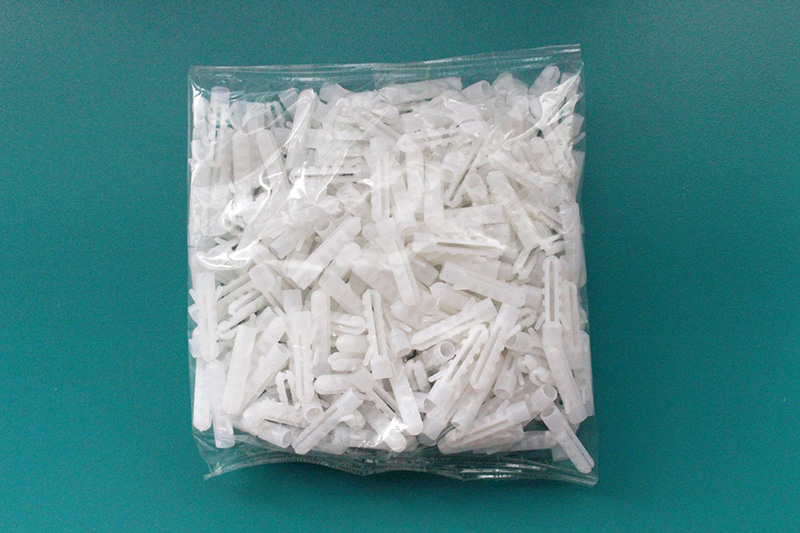

Applicable for weighting granular products with good flowability and small size such as Electronic Component: Transistor, Diode, Triode, LED, Capacitor;

Plastic: Caps, Spout, Valve; Hardware: Screw, Bearing, Spare Parts.

Features

• PLC program system with human-machine interface offer logical, intelligent & accurate control function .

• Adopt imported weighing load cell , high automation, easy to operation.

• Suitable for weighing quantitative single products only.

• It is capable of weighing Max. Weight per bag : 500g ± 0.3g.

• Two Vibration Bowls for weighing, one big bowl for main weighing and the small bowl for small weighing supplement. It’s more accuracy.

• Part Orientation Funnels provide enhanced control of the part as it falls from the bowl through the detection weighing load cell.

• Once the pre-determined weight is reached, the product is funneled into a pre-opened bag, which is automatically sealed and dispensed, while another bag is indexed for loading.

• The operator friendly control screen features easy job set-up job recall and on board system diagnostics.

• The machine size is very compact can save the space.

The machine can used together with takeaway conveyor, bucket conveyor, online printer, checking weigher, thermal transfer over printer etc. according to the client’s requirement.

It is a flexible, high-speed, high-accuracy, automatic weighing, vibratory bowl feed system.

| Model | LS-300 |

| Packing size | L: 30-180mm, W: 50-140mm |

| Max film width | 320mm |

| Packing material | OPP, CPP, Laminated film |

| Air supply | 0.4-0.6 MPa |

| Packing speed | 1-10 bag/min |

| Power | AC220V 2.5 KW |

| Machine size | L 1300 x W 1000 x H 1750mm |

Factory

Honor and qualification

images

Team

exhibition

group photo

travel

performance